Using AI to optimise sugarcane planting practices

Compared to whole-stick planters, growers using billet planters typically plant three to four times more seed cane to compensate for:

1. Uncertainties as to the viability of the seed cane which is reduced due to damage through the harvest-plant process and the planting of less-viable single node billets.

2. The compounding uncertainties in the measurements used when planting (bin weight, weight per billet, eyes per billet and percentage viable billets).

3. The mass-flow control mechanisms used offer little control with measured rates varying by more than 100% within a few metres.

4. Poor billet to soil contact can occur and is made worse by uneven billet distribution along the row. When clumping of planted billets occurs, adding more billets further exacerbates this problem.

Poor planting can lead to reduced yields as demonstrated by our Ballina trial where the mean gap between emerged plants was 59 cm which indicates a 30% loss in the yield potential for that field. While the trial field was not planted under ideal conditions, it demonstrates the potential impact. It is under non-ideal planting and early establishment conditions where poor planting is likely to significantly impact yield.

Typically, a grower must wait for the planted billets to establish before gaps become visible and then it is too late in the season to remedy. To compensate, a lot more billets are planted to try and avoid gaps as the operator cannot accurately:

1. Assess the quality of the seed cane.

2. Assess the number of eyes being planted per metre.

3. Control the feed of the planter for a uniform distribution down the furrow.

4. Control billet placement and associated bridging of billets.

Because growers/contractors cannot accurately measure actual planting rates, they continue to significantly overplant.

Acknowledgement

This project is fully funded by the Department of Primary Industries and managed by Sugar Research Australia.

Objectives

This project expands upon prior collaborations on multiple projects between Griffith University and industry, in particular:

• With Davco as part of the ARC Industrial Transformation Research Hub focused on enhancing farming productivity and disease prevention.

• With the SRA and Sunshine Sugar, ‘Billet Quality Assessment’ Small Milling Research Project.

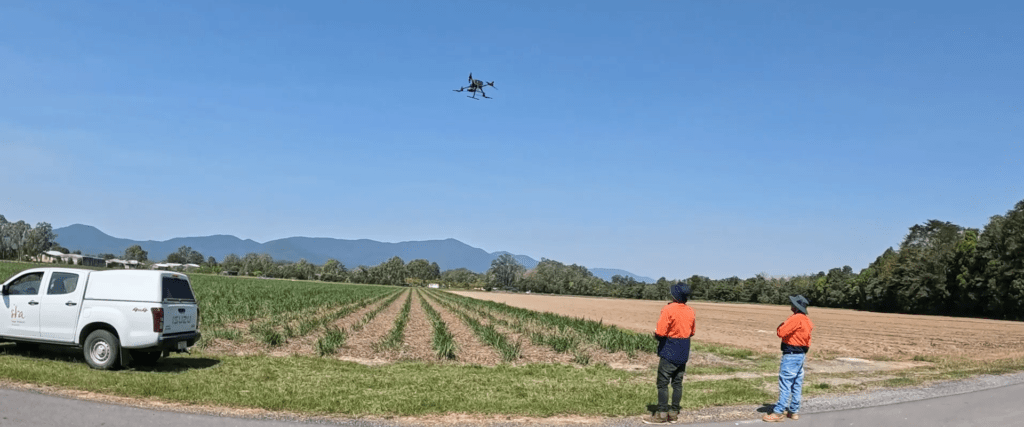

The project aims to improve planting by developing a System with AI capabilities that can measure billet planting rates and assess billet viability. This system can be used at either:

• The seed cane harvester to provide early notification of seed cane quality issues, or

• On the planter, with the capability to provide real-time feedback included the option of closed loop planter control.

The project will explore how this real-time information can be used to improve planting with the primary objectives of a more uniform strike with fewer gaps whilst using less seed cane. We will investigate:

1. Reducing machinery and agrochemical inputs and associated environmental benefits.

2. Monitoring of seed cane quality at the harvester.

3. Impact of seed delivery chute configurations.

4. Uniformity of delivery across rows for multi-row planters.

5. Impact of germination potential of rubber versus steel rollers.

6. The feasibility of closed-loop control of the billet feed.

7. Relative performance of different planting mechanisms.

8. Agronomic impacts of changes to planter configurations.

9. Providing manufacturers with immediate quantitative feedback to improve their designs.

10. How the system can provide industry with a tool for ongoing research.

11. How the system can be used for more effective demonstrations.

Expected Outputs

• AI model for billet viability assessment.

• Real-time monitoring system for planting rates and viability of billets.

• Field trial data and reports on agronomic impacts of planter configurations.

• Publications, presentations, and industry engagement materials.

• Final recommendations for planter design and industry adoption strategies.

Expected Outcomes

This project aims to provide the industry with a low-cost, easy-to-use, robust tool enabling growers and contractors to measure viable nodes planted per metre. This can lead to several significant changes:

Planting Management: Growers will be able to continuously assess billet quality at both at the harvester and planter as well as actual planting rates in real-time, empowering better-informed agronomic decisions and equipment choices.

Closed Loop Control: Closed loop control will enable further improved uniformity of planting distribution with the possibility of filling in non-viable billets.

Economic: Improved measurement accuracy could reduce the required seed-cane from 10 to 8 tons/ha (or less), saving approximately $98 million annually by redirecting saved cane to the mill. Reducing gaps could potentially increase yields by 1%, adding $29 million annually to the industry.

Adoption: Initial adoption is expected to be slow. Broader adoption will follow as the benefits are demonstrated which is likely to be subsequent to this project.

Decision-Making: Detailed performance reports on planting mechanisms and harvester modifications will enable growers to make informed equipment decisions.

Training and Extension: Field days, conferences, and publications will enhance the knowledge and skills of the community, driving improvements in planting efficiency, economic performance, and sustainability across the industry.

Licensing: There is potential to license the technology in Australia and to manufacturers in other sugarcane growing countries.

CHIEF INVESTIGATOR: Rudi Bartels

END DATE: 31/12/2028

Acknowledgements